Most of the procurement staff in the electronics factory have been confused by the variable price of PCBs, even some people with years of procurement experience may not all understand the reason. Customers want to get PCB products with high-quality and low cost. But the cost of the PCBs is no decline under the fierce competition of the electronics market. Why? Because the PCB price composition is complex and will change with many factors. Let us take a closer look at them.

The factors that affect the PCB price

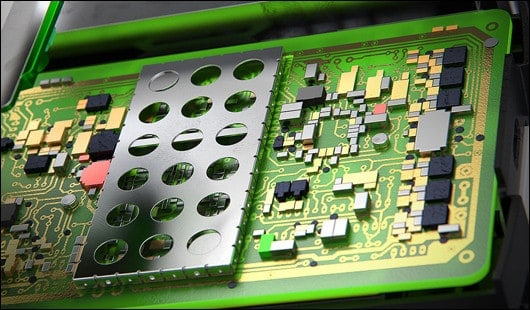

1. Different board materials

Material is an essential factor in price composition. First, different substrates result in various prices. FR-4, FR-1, CEM-1, and CEM-3 are common substrates that have different prices. And the cost of the substrate with varying degrees of TG is also different. At the same time, the price of the same substrate with the same specifications from different suppliers may be different, too. Second, there is much price difference about the board thickness from 0.6mm to 3.0mm and the copper weight from 0.5oz to 3oz. Third, the layer number of the PCB also causes a huge difference in the cost.

2. Solder mask and silkscreen

Solder mask and silkscreen are additional process steps in PCB manufacturing. The brands and varieties of the ink used in the solder mask will determine the price. The PCB price will be increased if you add these processes. But sometimes some PCB manufacturers provide these services for free.

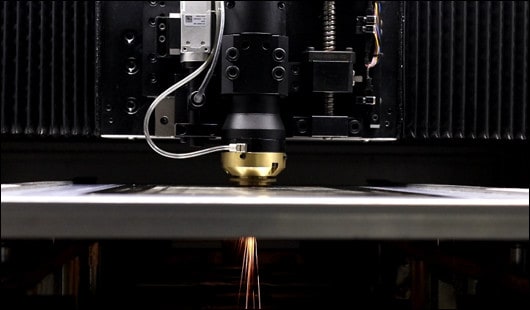

3. Different process demands

Different surface finish processes in PCB production have diversity price: immersion gold with the highest cost, then leadless HASL, HASL, and OSP are cheaper. Other conventional processes also have different charges, such as Immersion tin, immersion silver, and immersion gold, etc. Different routing and impedance control will also affect the final PCB production cost. Silkscreen-pattern and dry film-pattern also will cause a difference in the price.

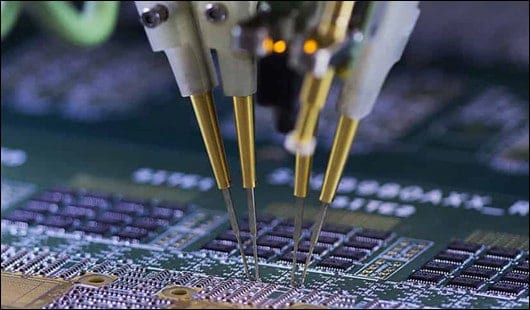

4. Different technical difficulty

Even if the same materials and the same processes, but the technical difficulty in PCB manufacturing will also cause different prices. The price is different if the hole diameter and line width are different. E.g., line width or line space is less than 4mm; the hole diameter is less than 0.6mm; these situations will increase the cost.

5. Other unique requirements

The process standards also affect the manufacturing price. The higher the standard, the higher the price. The common manufacturing standards are IPC2, IPC3, enterprise standard, and military standard, etc. Besides, PCB manufacturers will recalculate the price according to the different payment methods. And there is usually an extra charge for expedited services. PCB price composition is the most complicated in all industries; it needs to calculate from the cost of materials, manufacturing, package, transportation, lead time, etc. Anyone step may lead to the price difference. Price, lead time, and quality are the most issues that customers concern. Professional teams from PCBGOGO will give our customers reasonable suggestions to help them