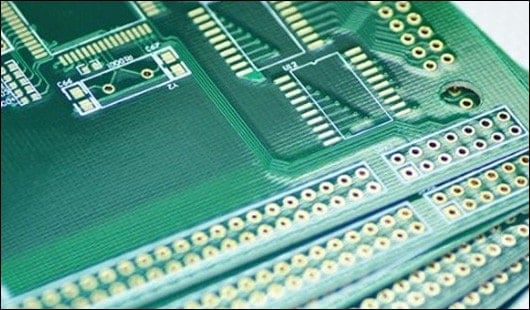

Printed circuit board (PCB) materials usually include the substrate, laminate, copper foil, solder mask, and nomenclature (silkscreen). The different materials used in PCB design and manufacturing have a variety of advantages and disadvantages. PCB designers should select proper materials depending on the application fields, the desired results, environmental factors, and other constraints faced by the PCBs

The importance of PCB materials in PCB manufacturing

PCB manufacturing is a complex process. All the materials and fabrication steps require specific materials for corresponding functions. And whether these materials are left on the board or removed during the fabrication process, all of them will affect the PCB’s manufacturability, reliability, and performance of the final products.

Besides, the selection of PCB materials affects the manufacturing cost. Cost priority or performance priority also is an important factor in selecting materials. So, when choosing the PCB materials, we should be aware of the electrical requirements of a given device and project budget.

Substrates and laminates

The substrate is the material with that the most choices in the PCB materials. Various standard substrates can be used to manufacture PCBs according to different requirements. Typical substrates are FR-1 to FR-6, CEM-1to CEM-6, GEM-10 to GEM-11, aluminum, metal substrates, PTFE(Teflon), Polyimide, etc. FR-4 is the most commonly used among these materials because it is versatile and low cost.

The substrate and laminates together define the necessary electrical, mechanical and thermal properties of the board.

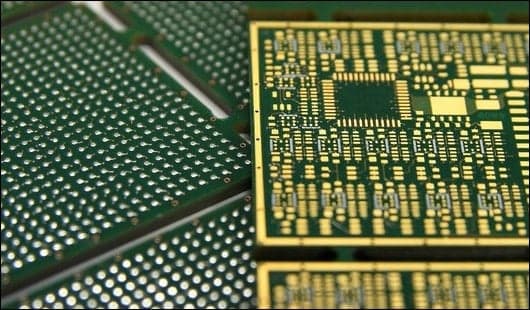

Copper foil

Copper foil is the conductive layer of the PCB, which has a particular influence on the electrical performance of the electronics. Generally, copper foil is divided into calendaring copper foil and electrolytic copper foil. Calendaring copper foil is suitable for high-performance PCBs, and electrolytic copper foil is used for conventional PCBs.

Solder mask

The color of the solder mask usually is green for most people’s regular impressions, but it also can be red, yellow, blue, or other colors due to some special requirements. Solder mask is an epoxy coating that acts as a protective and isolation layer.

Nomenclature (silkscreen)

Silkscreen usually is the white letters that you see on the solder mask, which indicates the position and the orientation of components. Except for the white color, silkscreen is also available in other colors.

Some factors that affect PCB designers to select the PCB materials.

Thermal performance

Dielectric constant (Dk)

Glass transition temperature (Tg)

Coefficient of thermal expansion (CTE)

Flame retardant

Signal loss factors

Mechanical strength

RoHS/UL

Most customers want to build PCBs with excellent performance at an economical cost. The first step is selecting suitable materials for your PCB type. The unique characteristics of these materials are significant in determining the functions, performance, and life cycle of the PCBs. If you would like more information about PCB material selection or how to choose the materials that best suit your PCB design, please contact us. We provide not just good materials but a complete solution. You will get smaller and smarter PCBs with excellent performance and high reliability from MUC.