What Single Sided Flexible Printed Circuit (FPC) is:

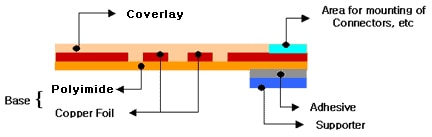

A single sided flexible printed circuit (1 layer flex circuit) is a flex circuit with one layer of copper trace on one substrate (normally Polyimide), and with one layer Polyimide coverlay laminated to copper trace so that only one side copper will be exposed, so that it only allowing access to copper trace from one side, comparing to dual access flex circuit which allows access from both top and bottom side of flex circuit.

As there’s only one layer of copper trace, so it also named as 1 layer flexible printed circuit, or 1 layer flexible circuit, or even 1 layer FPC, or 1L FPC.

This is the simplest stack up of flex circuits and also the most popular flexible circuit board used before, because the thinnest thickness, 1 layer FPC is the most flexible than other types FPC and this is one of the reason why people turn from Rigid Board to flexible board.

The lead time is the shortest (can be made within 24 hours) as you can see the manufacturing process is compared simple. If you want to replace the wire/cables to reduce assembly difficulty and avoid potential mistake, the single sided flex circuit is the best solution.

1 Layer Flexible Printed Circuit (FPC) Stack Up

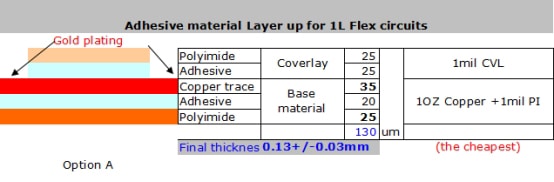

For the normal flex circuit, there’ll always be adhesive layer between Polyimide and copper, and the thickness is similar like Polyimide, so people will choose to “ignore” that layer and you will not see it in most of time. But for better understanding, we will list it bellowing:

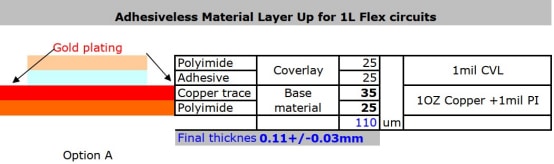

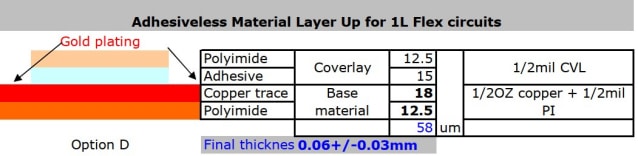

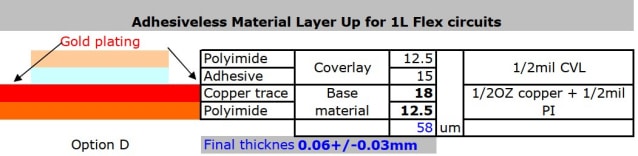

If you want thinner thickness and more flexible, then adhesiveless base material will be your choice. There’s no adhesive /glue between copper and Polyimide, so the total FPC thickness will be thinner than the same FPC with same copper and Polyimide thickness. See stack up bellowing: (0.11mm VS 0.13mm)

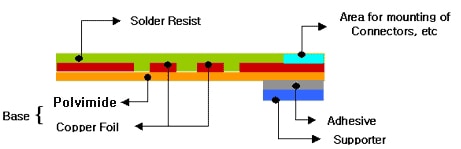

In normal stack up, adhesive layer will be hided so that customer can focused on other more important elements. Bellowing is two stack up /layer up and the only different is Coverlay material: One is Polyimide (the most popular one) and another is soldermask oil