Double sided flexible circuit board consists of double-sided flexible copper clad material with coverlay opening on one or two sides. There’re two conductive trace layers (normally copper) with an insulating layer (normally Polyimide) in the middle, and two conductor layers were electronic connected via plated through holes (PTH). Sometimes, there’s no PTH in double layer flexible circuit, as the design purpose of bottom trace is to support rigidness of circuit, or as impedance controlled, or other special purpose.

The coverlay was made of Polyimide and already pre-cut before laminated to copper trace, so that the trace PAD and gold fingers can be accessed from both sides through the coverlay or soldermask opening. Flexible Oil also can be used as coverlay or soldermask to protect traces from oxidation and soldering.

2 Layer flex circuits allow for more complicated circuit designs than a single-sided FPC and a dual access FPC , increase the wiring density per unit area, and further space savings are realized by mounting components on both sides.

All stiffener, adhesive tape, EMI shield material and other material can be placed on anywhere of double layers circuits.

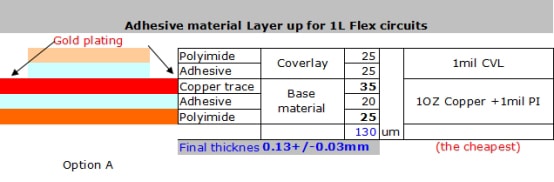

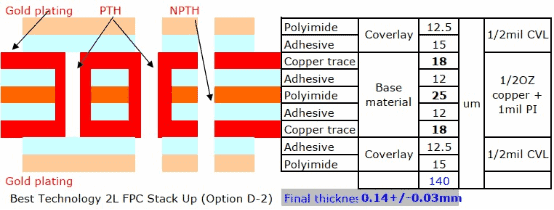

Double Sided Flexible Circuit Stack Up / Structure

As double sided FPC is the most popular type of flexible circuit, so there’re various combination of different material. There’re five basic layers, from top to bottom (didn’t list the adhesive between):

- Coverlay (top)

- Copper trace (top)

- Polyimide: between two copper trace

- Copper trace (bottom)

- Coverlay (bottom)

Here is the most popular stack up /layer up of double layer flexible circuits:

Adhesiveless laminate also available and in fact, it’s very popular, as engineer want thinner thickness, bigger bend radius, chemical and high temperature, low outgassing, dimensional stability, more flexibility, longer life cycles, and impedance control and so on.

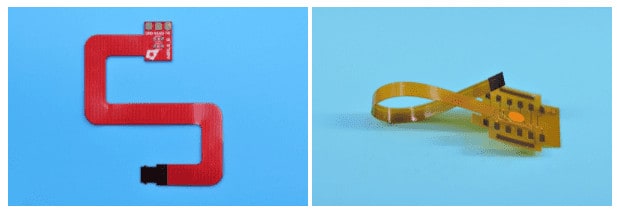

Double Sided Flex Printed Circuit Board Samples

Here are pictures of double sided flexible circuit produced by us.

Capability of Double Side Flexible Circuit:

Copper thickness: 1/3OZ, 1/2OZ, 1OZ, 2OZ, 3OZ, 4OZ

Polymide thickness (in base material): 1/2mil, 1mil, 2mil, 3mil, 4mil

Board thickness: 0.10mm ~ 0.44mm

Maximum Dimension: 220*1,500mm

Min PTH: 0.10mm

Min LW/LS: 2mil/2mil (0.5OZ)

Impedance control: Most popular values are 50 ohm, 90 ohm, 100 ohm, other values also available

Manufacturing Process of Double Sided Flex Circuit

Here is simple manufacturing process of double sided flex circuits, welcome to visit MUCPCB factory in China, to see the real manufacturing process of flex circuit, then you will know better how to make 2 layers flex circuit, to see how MUC transfer your circuit board layout into real flex circuit.